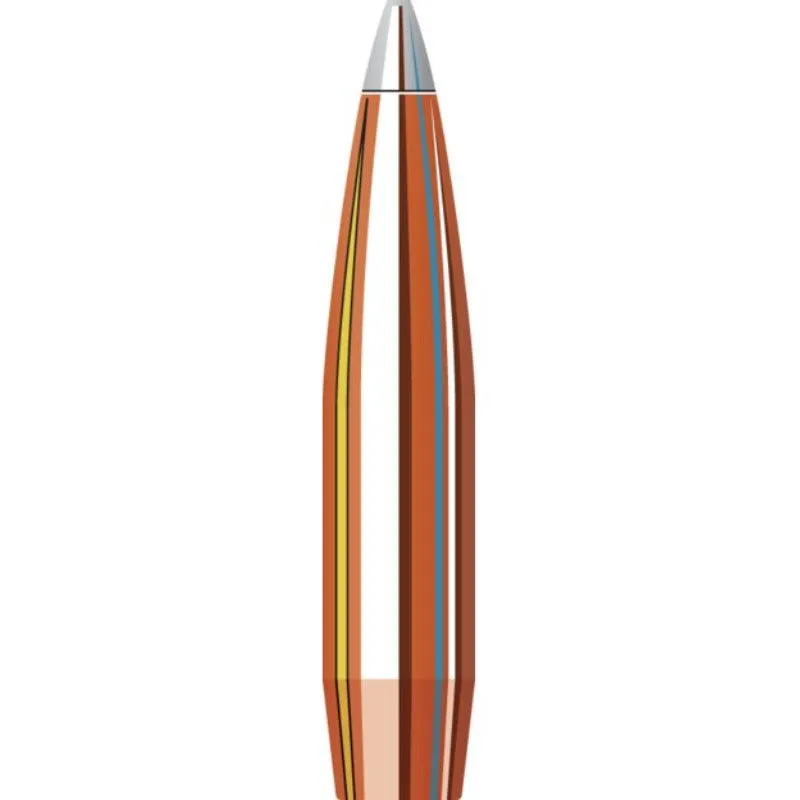

Years of meticulous research and rigorous testing conducted by the Hornady® Ballistic Development Group, alongside cutting-edge manufacturing techniques and stringent quality control protocols, have culminated in the creation of the ultimate low drag, high-performance match bullet. Utilization of the innovative A-TIP™ seating stem is essential for achieving optimal bullet seating.

Product Features:

- Tip Design: The aluminium tip, meticulously machined and longer than conventional polymer tips, strategically shifts the centre of gravity, thereby enhancing in-flight stability. The aeroballistically advanced tip design yields tighter groups and minimized drag variability. Each bullet boasts a meticulously crafted blend of ogive, tip length, bearing surface, and caliber-optimized boattail.

Performance:

- Doppler radar-validated low drag coefficient (high BC) bullets exhibit remarkable forgiveness concerning twist rate, seating depth, and muzzle velocity. The refined design of the AMP® bullet jacket ensures industry-leading uniformity and concentricity.

Manufacturing:

- Straight from the press, each bullet is meticulously packaged sequentially, maintaining an impeccable clone-to-clone consistency for unparalleled performance. Throughout the manufacturing process, minimal handling is maintained to ensure consistency from bullet to bullet. Furthermore, each package includes a polishing bag, preparing bullets for loading without the need for bulk washing post-manufacture.